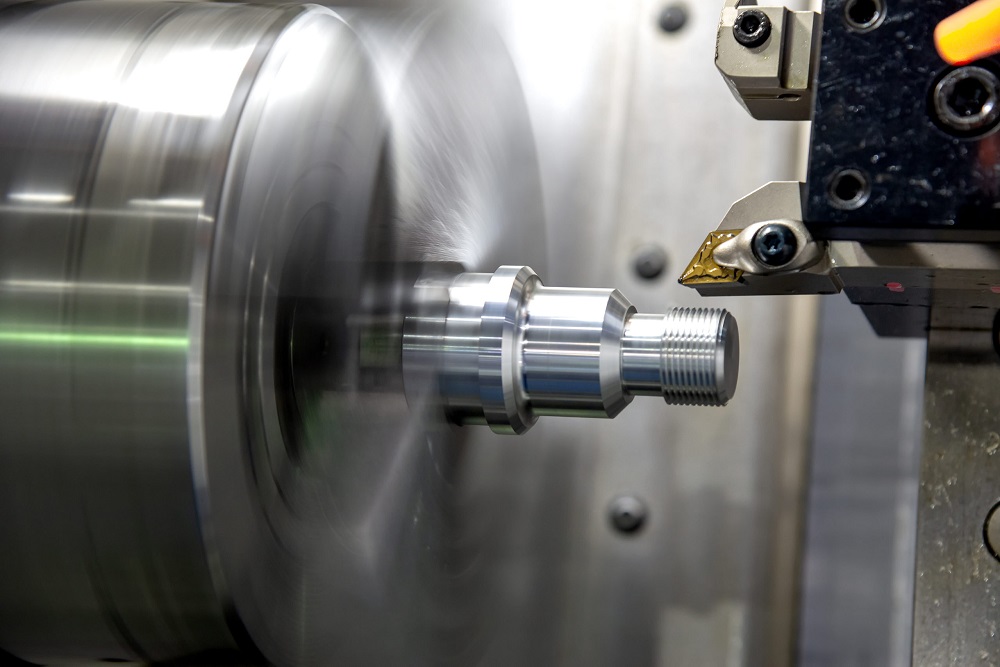

For CNC machines, the full name is (Computer Numerical Control) is an automatic machine that works with a computer system. To produce pieces or create materials to the desired size and shape by turning. Suitable for precision or complex turning operations. In Thailand, CNC machines that are imported to use are mostly in the factory industry with the creation of various parts of the Motorsport industry. Nowadays, CNC machines from abroad have been used in the Motosport industry to produce. The workpiece meets the desired specification. Because most motorsport lathes are made in the form of cylinders, cylinder blocks, valve caps, and many others because of computerized control.

CNC Machine Work

What Are The Advantages Of A CNC Lathe Over Other Brands Of Lathes?

When you look at CNC lathe for sale (ขาย cnc lathe, which is the term in Thai) for metal cutting tools, you will find that many manufacturers are ready to provide cost-effective metal cutting services to meet your needs. Today’s manufacturing industry relies on machine control (CNC) by computers. Including operations that have been used by engineer control, such as planning machines, lathes, and millers.

What Is A CNC Lathe?

A machinist can program a CNC lathe to cut tough materials such as brass, carbon steel, aluminum, plastic, titanium, stainless steel, and more, and can produce quality parts at consistent rates. Two types are as follows

- Lathes Set

- Lathes

Horizontal CNC lathe turning cylindrical while the material cutting tool will cut off the excess material Materials must be placed vertically and against gravity. Horizontal lathes tend to take up a lot of setting up space, making them suitable for use with small to medium-sized materials.

Benefits Of Using A CNC Lathe

CNC lathes are operated through a PC program. However, they are different from conventional pcs because they use software with lathe control. The CNC software is specially programmed and customized with a G-Code (dedicated CNC language) for the control. Precision tasks such as position, coordination, speed, and feed rate

Most manufacturers use the latest tool control software to customize the surface and control material cutting times. While still having to maintain performance by the 3D product design requirements.

Why Is CNC Better Than Conventional Machines?

Although they have the same goal of use, both have fundamental differences between CNC and conventional lathes. It is a CNC automation system with a general lathe control system.

CNC lathes require employees to program software that is skilled in machine control. But general lathes require employees to perform everything in their work.

In addition, highly skilled operators will have to set up their gears manually. While using a CNC lathe, gears are not used.

In Terms Of Costs: They are generally less costly than in smaller projects. But in general, the use of CNC lathes is used in high volume workload operations.

Speed, Production Rate, And Accuracy: It is an advantage of CNC lathes, which is significantly more capable than conventional turning.